Foundry

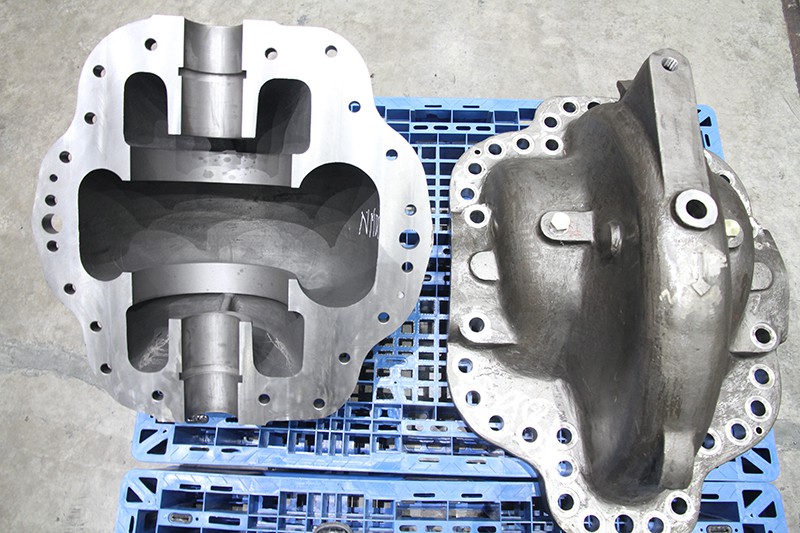

Trinity’s state of the art foundry, approved by American Bureau of Shipping (ABS) for cast steels and spheroidal iron castings, is fully equipped to provide quality sand castings to international standards (ASTM, DIN and JIS). The facility houses modern induction melting furnaces, an automated sand mixer with PLC controls and reclamation plant, a CNC pattern shop, heat treatment furnaces, CNC induction hardening and an analytical metallurgical laboratory.

The foundry is capable of single piece castingof cast iron up to 7 tons, steel up to 4 tons and non-ferrous up to 1.5 tons. Types of materials casted include plain-carbon steels, high tensile alloy steels, corrosion resistant stainless steels - ferritic, martensitic, duplex & super duplex, wear resistant manganese steels, abrasion resistant cast irons, nickel alloys, cast irons, ductile irons, alloyed cast irons, quenched and tempered steels.

Over the years, the foundry has successfully challenged the traditional wisdom in producing one off products of demanding grades and in turn earned the respect from its clients. We cater to various industries (marine, oil & gas, dredging and pumps) producing numerous parts such as:

- Dredging components (liners, wear plates and spud carrier parts)

- Pump components (impellers, wear rings, diffuser bowls and casings)

- Blow bars

- Gearbox housings

- Crusher wear parts

- Sheaves

- Gypsy wheels

- Marine thruster parts

- BOPs

-

Foundry

-

Foundry

-

Foundry